Measuring OLED displays in production environments

Displays are being integrated in more devices than ever. Nowadays displays are used in cars, phones, tablets, laptops, watches, household appliances, etc.

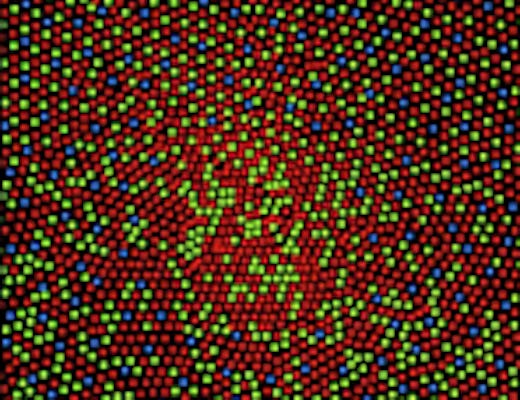

LCD has been the dominant display technology for many years, during which the technology matured and reached its limits with respect to resolution, brightness, contrast, color saturation and speed. There have been multiple display technologies aiming to replace LCD of which only a few seem capable to actually challenge it. And now, nearing the end of this decade, OLED technology is on its way to push LCD aside.

Major mobile phone and tablet manufacturers are already using OLED displays in their top-tier product lines because of their superior contrast and color saturation. These properties give manufacturers a competitive advantage, but they also create challenges when measuring these displays in their existing measurement systems. These measurements need to be done to accurately calibrate every display, so color performance is constant for each device.

Need for highly sensitive and accurate colorimeters

The colorimeters used for LCD technology performed very well for many years in mass production environments.

However,

when re-using these systems for OLED display technology they will be

relatively slow. The internal sensors need a minimum amount of light for

accurate measurements, and the deep OLED black levels offer less light

to measure. This will result in longer measurement times during which

more light is collected to compensate. Sensor technology and electronics

will need to improve so measurement time can be shortened for measuring

the black level of OLED displays.

Furthermore, re-used systems

may be less accurate on OLED displays as well because the emitted light

has other spectral characteristics than LCD. Within the colorimeter, the

transmissive filters which create the XYZ tristimulus functions have

spectral imperfections and will need to improve so the color

measurement will be more accurate.

To optimise tact times while

still maintaining high measurement accuracy in mass production

environments the OLED display and device manufacturers need more

sensitive and more accurate measurement equipment.

Introducing the Admesy Prometheus colorimeter

Admesy has developed the Prometheus colorimeter

which integrates custom-designed optical filters, state-of-the-art

electronics and sensors in a compact robust housing. The Prometheus is the

perfect choice for manufacturers who need fast and accurate OLED

display measurements for their products.

The Prometheus has a proven

track record for OLED white-point adjustment, gamma correction, flicker

analysis and contrast measurements at major display and electronics

manufacturers.

Need more help in selecting the right display measurement device? Experts in color and measurement systems with a background in display technology manufacturing at Admesy will gladly give you the advice you’re looking for.