Using Spectrometers and High-speed Light Meters to Monitor LED Performance

A light-emitting diode (LED) is a semiconductor light source that now finds use in a lot of applications due to its many benefits. LEDs use the effect of electroluminescence, which is where electrons recombine with electron holes and release photons when electricity is applied.

The increased use of LEDs is due to its

many benefits. They are more energy efficient, have a longer lifetime,

are smaller, and more robust than other light sources. They find use in

the automotive, aviation, medical industries and domestic applications

to name a few. With this increase in the use of LEDs, it is important

that they perform well.

Common Issues with LEDs

While LEDs are considered an improvement compared to traditional light sources, they can still have their issues. When LEDs are produced, there can be vast differences in optical properties, despite being from the same batch. To ensure that LEDs maintain the high-quality properties, they need to be monitored during production to prevent any variation in color or brightness.

Flicker is another common issue with LEDs that typically appears when combining drivers and power supplies to LEDs. Flicker is the effect of fast and repetitive changes to the brightness levels of LEDs, which is not caused by the LED itself, but by the combination of other electronics involved in the electrical design. There are two types of flicker; visible and invisible which both can be harmful to humans.

Visible flicker can be perceived by the human eye, and it can cause seizures in people with photo-sensitive epilepsy. Invisible flicker is not perceived by the human eye, but it can still affect humans and cause headaches, nausea, and eye strain.

Ensuring LED Quality

Resolving the issues with inconsistent quality and flicker can be done during the production of LEDs using a spectrometer and high-speed light meter. A spectrometer is a very versatile instrument, and various lighting measurements can be performed to improve the quality of LEDs.

Radiance and irradiance measurements are extremely useful for LED quality control. These measurements provide data regarding the LEDs energy intensity. Using these measurements, the light sources can be compared and their lumens, lux, and candela can be measured.

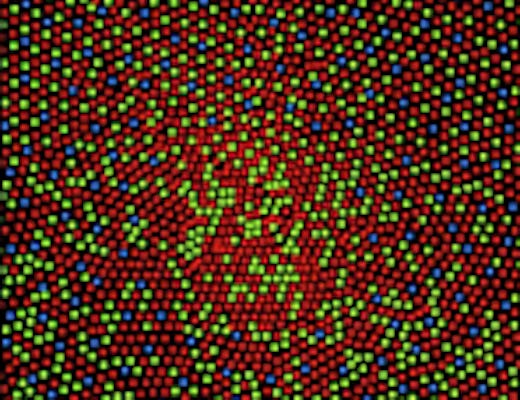

Spectrometers can also be used to perform gamut calibration, which works by calibrating the white point first, then tuning the maximum red, blue, and green values to each LED has the exact same output. A spectrometer is used to measure the red, blue, and green values, translates these to XYZ and Yxy values and uses these three color points to determine the color gamut. Gamut calibration helps to reduce any color variation between LEDs. This white point or gamut calibration allows creating exactly the same color palette for LED light sources even if the single LEDs used are different.

As spectrometers are typically integrating devices, these cannot be used to carry out flicker measurements. For these purposes, high-speed light meters matching the luminosity function are used to detect rapid changes in light output over time and calculate the amounts of flicker.

Accurate spectroradiometers and light

meters are required to ensure LED quality and Admesy manufacture and

supply a range that performs excellent lighting measurements. If you

would like any more information about the range of spectrometers and high-speed light meters from Admesy, please contact us.